Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The important features of the membrane switch

1, small and light: general membrane switch weight for a few grams to dozens of grams, very easy to carry and disassemble;

2, beautiful: modern perfect screen printing technology, with the perfect design, you can make any pattern you need;

3, sealing: the use of unique technology, can make the membrane keypad switch with waterproof, anti-oil, anti-pollution, anti-static interference and other functions;

4. Excellent conductive performance: the circuit of the switch can be printed with carbon paste, silver paste, copper and platinum, and the conductive layer can be folded at will; And the resistance can be controlled in any resistance you want to need, and, using a unique technology, the membrane switch can even accept tens of thousands of volts of high voltage electric shock without damaging its function;

5, low cost: some membrane keyboard switch selling price even only a few cents, relative to a has so many functions of the electronic raw device products, its price advantage is not other similar products can achieve.

6, long service life: because the membrane switch used by the material has good insulation, heat resistance, flexibility and high resilience; And the printing of the pattern are printed on the reverse side, so that the silk screen pattern will not be damaged; Therefore, the service life of the membrane switch can generally reach more than three years.

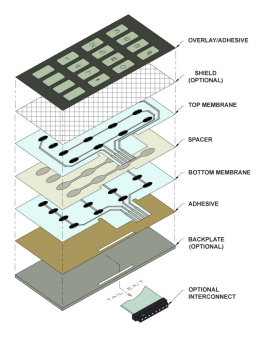

Common membrane switch disassembly and assembly diagram:

Common membrane switch components of the material

First, the panel layer

The panel layer is generally less than 0.25MM PET, PC and other colorless transparent sheet screen printing on the fine pattern and text production, because the most important role of the panel layer is to play the role of identification and keys, so the selection of materials must have high transparency, high ink adhesion, high elasticity, anti-bending characteristics.

Two, rubber layer

The most important role of the cushion layer is to closely connect the panel layer with the circuit layer, so as to achieve the effect of sealing and connection. The thickness of this layer is generally required to be between 0.02- 0.05MM, with high viscosity and anti-aging; In the production, the general selection of special film switch double-sided adhesive, some film switch requirements can waterproof and high temperature, so the rubber layer must also be used according to the needs of different properties of materials.

Three, control circuit upper and lower

This layer adopts good performance polyester film (PET) as the carrier of switching circuit graphics and on it with a special process silkscreen silver pulp carbon pulp or gold pulp to make it conductive, its thickness is generally within 0.05--0.175MM, the most common is 0.125MM PET

Four,Laminated layer

It is between the upper circuit and the lower circuit layer and plays the role of sealing and connecting, generally using PET double-sided adhesive, its thickness is 0.05-0.2mm; When selecting this layer of material, the overall thickness of the product, insulation, feel of the circuit key package and tightness should be fully considered.

Five, back rubber layer

The use of adhesive and membrane switch and what kind of material is closely related to the paste, the common double-sided adhesive, 3M adhesive, waterproof adhesive and so on.

Keypad switch, panel material, in addition to the requirements of flatness and printing adaptability, more important is to have the characteristics of flexibility and high elasticity.

Types of materials

PVC\60℃\0.175~0.5/ smooth \ stable to acid, base and salt at room temperature. Good wear resistance, fire resistance, noise and shock, good electrical insulation. Poor thermal stability.

Polycarbonate PC\-60~120℃\0.175~1.0\ smooth surface high transmittance, low water absorption, good dimensional stability, bending, tensile, compressive strength is very superior, heat resistance and cold resistance, electrical insulation and atmospheric aging resistance excellent. Drug resistance is poor, fatigue resistance is poor, easy to produce stress cracking, output interface terminal circuit is generally printed with carbon material, and no protective coating, by air oxidation gradually formed off layer, to finally lead to the end of the life, this is the film switch most prone to failure, mainly determined by the environment, whether used or not, Physical damage time is 3-10 years. Generally applicable to the most extensive range, in addition to meet the requirements of most membrane switch panel, which smooth PC high transmittance can also meet the requirements of a liquid crystal display window.

Sand surface polyester (PET)\-30~120℃\0.1~0.2 smooth surface \ good drug resistance, insoluble in general organic solvents, no alkali resistance. With excellent mechanical properties, electrical properties, rigidity, hardness and thermoplastics in the largest strength and toughness, low water absorption, wear resistance, good friction resistance, high dimensional stability. Tensile strength can be comparable to aluminum film, much higher than PC, PVC. Low because the surface is difficult to process into matte type, textured PET is more expensive is the most ideal substrate for making film switching circuit. Textured PET is suitable for products with high surface requirements or liquid crystal display Windows.

Thickness of material

The thickness of the plastic substrate is 0.25mm and below known as the film, mainly used as the film switch panel layer, its back printed with a variety of indicative patterns, text to indicate the operation area of the corresponding switch key, the thickness of the selection should depend on the size of the panel and the key, the thickness of the material, increase the touch force, slow response; The material is too thin, feel poor when touching, bounce back is not obvious. Thickness of 0.25mm above called plate, not suitable for three-dimensional key forming, can be used as no key operation area of the indicator sign panel, can also be used as a film switch lining board to improve its hardness.

Line layer printing material:

The substrate for making the circuit should be polyester (polyethylene glycol phthalate) film (Potyester for short PET). It has good insulation and heat resistance, high mechanical strength, transparency and air tightness, especially with flexibility and high elasticity, is the ideal material for making film switching circuit.

membrane switching structure

1) Flat non-tactile type:

Long service life, but no touch;

2) Convex touch type of film:

Good touch, but relatively short service life;

3) Convex frame type non-tactile type:

Beautiful appearance, there is a strong three-dimensional sense, but no sense of touch;

4) Convex frame touch type:

Beautiful appearance, strong three-dimensional sense, and touch;

5) Face plate convex touch type:

(a) type: when the design is not appropriate, it is easy to have two sections, but the surface is damaged, and the electrical performance is also there;

(b) type: there is no two-section phenomenon, and the structural layer is less, more economic, if the plate is damaged, electrical performance will not exist;

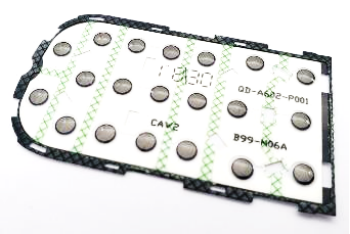

6) Metal shrapnel type:

Type (a) : is the most basic and most commonly used structure. Shrapnel acts both as a touch and as a wire;

Type (b) : Complex structure, used for shrapnel more dense and do not have jumper occasions. Shrapnel on the line on the road, the conductive surface of the upper and lower lines are up, the line needs to punch. This structure is conductive when the four feet of the shrapnel and the center point is not in the same plane, there are "two sections" of the situation. At the same time, the shrapnel is often in excessive concave strong state, for a long time, the shrapnel will not rebound phenomenon, not recommended;

(c) type: shrapnel on the line on the line, only touch the role, the upper line conductive face down, the lower line conductive face up, there are "two sections" of the case, not recommended;

(d) type: shrapnel is placed on the lower line, the upper and the lower line are wired, shrapnel both plays the role of touch and play the role of connecting the upper and lower lines; Used for more shrapnel, more dense and do not have jumpers, the structure is simpler than (b) type. The design should pay attention to the line to avoid the four legs of the shrapnel, to ensure that there is no short circuit.

7) Luminous body type: be sure to open the bottom rubber mold;

(a) LED line and the line under the same layer: simple structure, but the LED window should be convex, otherwise, the LED light will top the surface version; It is suitable to choose the height of the small LED lights or LED lights less occasions;

(b) LED line and the lower line of different layers: the structure is complex, but the LED window does not have to be convex, suitable for the use of two-color LED lights or LED lights a large number of occasions; Need to open punching die and bottom rubber die;

8) Anti folding:

This type can avoid jumper and do not need to fill holes can make the conductive surface can be downward, the structure of the shortcomings in the fold is easy to break the line.

9) Waterproof inside and outside frame type:

The outer frame is a closed frame with no wire running, and the inner frame plays a protective role to prevent water and air from entering the housing from the outlet groove.

Switch type

Flexible membrane switch

Flexible keypad switch is a typical form of film switch. This kind of keyboard switch is called flexible, because the membrane switch mask layer, isolation layer, circuit layer are all composed of a variety of different properties of the software film.

The circuit layer of the flexible membrane switch, all use polyester film (PET) with good electrical performance as the carrier of the switch circuit graphics, this layer is also divided into hand shrapnel, up and down the circuit. Due to the influence of the properties of polyester film, the film switch has good insulation, heat resistance, flexural resistance and high resilience. The graphics of the switching circuit, including the connection of the switch and its lead lines are printed with a low resistance, low temperature curing conductive paint. Therefore, the composition of the whole keypad switch has a certain softness, which is not only suitable for use on the flat surface, but also can cooperate with the curved surface. Flexible membrane switch lead line and switch body itself is one, in the production of group switch online, it will be collected in the film at a certain place, and according to the design of the specified position and standard line distance extended outward, as a soft, arbitrary bending, sealed lead wire connected with the machine after the circuit.

Hard membrane switch

A hard membrane switch refers to a switch whose graphics and wiring are produced on a common printed circuit covered copper plate. The characteristics of the hard keypad switch are simple materials, stable process, low resistance, and can be directly welded on the back of some components in the circuit. In the case of small area, hard lining layer can be omitted. Hard membrane switch generally uses metal guide as the labyrinth contact, so better feel. On the downside, it is convenient to install a less flexible membrane switch in the whole machine, which often requires welding plug-ins and leads through flat cables. In addition to the buzz signal and LED indication, the information feedback of hard film switch can generally use metal feel shrapnel.

Flat membrane switch

The key on the membrane switch, with different colors to indicate the position, shape and size of the key body, is more common in the initial stage of the keypad switch. Stereoscopic membrane switch: Usually, the keys on the keypad switch are simply colored to express the position, shape and size of the key body. In this way, can only rely on the operator's vision to identify the accuracy of the operation, because there is no appropriate feedback information to indicate whether the finger is pressed in the effective range of the switch switch action, thus affecting the confidence of the whole machine monitoring and operation speed. A membrane switch which makes the opening key body slightly convex and slightly higher than the panel to form a three-dimensional shape is called three-dimensional key switch. The three-dimensional key can not only accurately set the scope of the key body, improve the identification speed, so that the operator's sense of touch is more sensitive, but also enhance the decorative effect of the product appearance. The production of three-dimensional keys, must be arranged in the design stage of the panel, equipped with process holes, in order to press the mold when the precise positioning, the height of the three-dimensional projection should not be more than two times the thickness of the substrate. For the appearance of the product, the projection of the raised keypad switch can be varied.

Technical parameter

Electrical property

1. Working voltage: ≤50VDC

2, working current: ≤100mA

3, contact resistance: 0.5~10Ω

4, insulation resistance: ≥100MΩ (100VDC)

5, the substrate pressure: 2kDVC

6, rebound time: ≤6ms

7, circuit resistance: 50Ω, 150Ω, 350Ω three levels, or to the user needs to determine

8, insulation ink pressure: 100VDC

Mechanical property

1, reliability service life: > 1 million times

2. Closed displacement: 0.1~0.4mm (non-tactile type) 0.4~1.0mm

3, health standard force: 15~750g force

4, silver pulp migration: at 55℃, 90% temperature, 56 hours later, the second line between 10MΩ/50VDC

5. There is no oxidation or impurity on the silver paste line

6, silver pulp line width ≥0.3mm, minimum interval 0.3mm, line raw edge < 1/3, line gap < 1/4 line width

7, pin spacing standard 2.54 2.50 1.27 1.25mm

Lead out line resistance, roll 80 times with d = 10mm steel rod.

Environmental performance

1, working temperature: -20℃ ~ +70℃

2, storage temperature: -40℃ ~ +85℃ temperature 95%±5%

3, high gas pressure: 86 ~ 106KPa

Printing index

1. The printing size deviation is ±0.10mm, and the appearance edge is unclear and the knitting difference is ±0.1mm

2, color deviation ±0.11mm/100mm, insulation ink all covered silver pulp line

3, no ink, writing without incomplete

4, the color difference is not more than two

5, no crease, paint off

6, transparent window transparent clean, uniform color, no scratches, pinholes, impurities.

For maintenance personnel, some old equipment can not match the membrane switch used by the original machine, you can record the corresponding line number of the key, and then replace it with a general button (tap switch) plus a group of lines. The effect is exactly the same, but more work!

Membrane switch special 3M double-sided tape

1, non-woven fabric base material double-sided adhesive (composed of non-woven fabric base material double-sided coated acrylic adhesive) : such as 3M9448, 3M9080, 3M9075, etc. Adhesive viscosity and processing is good, generally long-term temperature resistance 70-80℃, short-term temperature resistance 100-120℃, thickness is generally 0.08-0.15MM, suitable for Ming board, plastic bonding, automobile, mobile phone, electrical appliances, sponge, rubber, signs, paper products, toys and other industries, home appliances and electronic instrument parts assembly, display lens.

2, no substrate substrate double-sided adhesive (directly from acrylic coating) : such as 3M467, 3M468, 3M9473, etc. No substrate double-sided adhesive has excellent adhesion effect can prevent falling off and excellent waterproof performance, good processing, good temperature resistance, short-term temperature resistance of 204-230℃, general long-term temperature resistance of 120-145℃, thickness is generally 0.05-0.13MM, suitable for Ming board, panel, decorative parts bonding.

3, PET substrate double-sided adhesive (composed of PET substrate double-sided coated acrylic adhesive) : such as 3M9495MP, 3M9795B, 3M9495LE. PET substrate double-sided adhesive has good temperature resistance, strong shear resistance, generally long-term temperature resistance of 100-125℃, short-term temperature resistance of 150-200℃, thickness is generally 0.048-0.2MM, suitable for Ming board, LCD, decoration, decorative parts bonding.

When the 3M double-sided adhesive is glued, it can obtain strong bonding effect by following operations:

1. The adhesive surface must be cleaned and dried first. It is generally recommended to wipe and clean the mixture of 1:1 IPA and water with cloth, and then dry the surface completely.

2. After the cleaning solvent has dried, attach the tape to the adhesive surface and apply a pressure of about 15PSI (1.05 kg/cm2) by roller or other means for effective adhesion.

3. Remove the adhesive tape release paper, and then paste the material to be fitted. Apply 15PSI pressure to make it fit effectively. If air bubbles need to be removed, the pressure should be increased to the upper limit of the item can bear.

4.paste the ideal temperature is 15-38℃, not less than 10℃.

5.When adhesive tape is glued, one end should be fitted first, and then slowly pressed to the other end, while tearing the paper and pasting to reduce the probability of bubbles.

The suitable environment requirements of 3M double-sided tape storage: temperature is 19-23℃, humidity is 40-60%.

3M double-sided tape is widely used in computers, mobile phones, communications, household appliances, audio-visual equipment, automobiles and other products. It should be selected according to the needs of the applied products and environment. Please refer to the following instructions:

1, non-woven fabric base material double-sided adhesive and processing good, generally long-term temperature resistance 70-80℃, short-term temperature resistance 100-120℃, thickness is generally 0.08-0.15MM, suitable for Ming board, plastic fit automobile, mobile phone, electrical appliances, sponge, rubber, signs, paper products, toys and other industries, home appliances and electronic instrument parts assembly, display lens.

2, no substrate double-sided adhesive has excellent adhesion effect can prevent falling off and excellent waterproof performance, good processing property, good temperature resistance, short-term temperature resistance 204-230℃, general long-term temperature resistance 120-145℃, thickness is generally 0.05-0.13MM, suitable for Ming board, panel, decorative parts bonding.

3, PET substrate double-sided adhesive has good temperature resistance, strong shear resistance, generally long-term temperature resistance of 100-125℃, short-term temperature resistance of 150-200℃, thickness is generally 0.048-0.2MM, suitable for Ming board, LCD, decoration, decorative parts bonding.

4, foam base material double-sided adhesive has soft, good adhesion, good initial viscosity and stickiness, good solvent resistance and UV resistance, general thickness of 0.4-1.0MM, short-term temperature resistance 130-150℃, long-term temperature resistance 80-93℃, suitable for air conditioner, office furniture, communication products bonding, can replace screw fixed design, make the product more beautiful.

5, hot melt film has good consistency, uniform bonding thickness, does not contain solvent, easy processing, many objects have good bonding, thickness of 0.1MM, color is translucent/amber, hot melt softening temperature 116-123℃. Suitable for nameplate, plastic, hardware bonding; Good results can also be obtained by bonding on uneven surfaces. The recommended initial bonding conditions are: temperature 132-138 ° C, bonding time 1-2 seconds, and pressure 10-20 lb/sq inch.

Customer related Case

The customer has developed a high-real-time operating system master station controller, which is equipped with advanced network terminal technology.

A fetal monitor is a medical device used by a pregnant woman to monitor the heart rate and uterine contractions of the fetus during labor to ensure the safety of the fetus during labor.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.